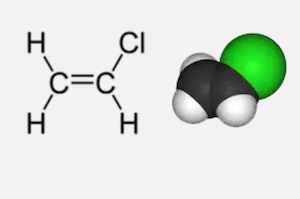

Vinyl Chloride Monomer (VCM)

C2H3CI

Vinyl Chloride Monomer (VCM) is a colorless gas with a faint odor. It forms a liquid readily under increased pressure or at reduced temperatures. VCM is used primarily in the production of Polyvinyl Chloride (PVC) homopolymer and copolymer resins.

Vinyl Chloride Monomer (VCM) is a colorless gas with a faint odor. It forms a liquid readily under increased pressure or at reduced temperatures. VCM is used primarily in the production of Polyvinyl Chloride (PVC) homopolymer and copolymer resins.

Properties

- Molecular Weight: 62.5

- Boiling Point: -14°C

- Freezing Point: -153.7°C

- Flash Point: -78°C

- Vapor pressure: (0°C):1750hPa(mbar) ; (20°):3400hPa(mbar) ; (48°C):7600 hPa(mbar)

- Specific gravity of liquid (water=1): (20°C):910kg/m3;(-14°C):970g/m3

- Relative vapor density/air: 2.15

Uses

The largest use for Vinyl Chloride Monomer is in the production of Polyvinyl Chloride (PVC) homopolymer and copolymer resins. These PVC resins are converted to products for a number of end-use markets.

More than half of the total VCM consumption is for construction-related applications, with pipe being the largest single product. Other products made from PVC resins include flooring, packaging film and sheet, and bottles.

Handling and storage

QVC recommends that prior to installing VCM storage facilities, you contact all concerned local government agencies, i.e., fire department, health department, environmental quality, etc. Local requirements may vary and any VCM installation should meet the standards of these agencies.

VCM spills may need to be reported to QVC Emergency No. 4476 5800 (24hrs). Disposal of spill material should be in compliance with local regulations. More information on the safe handling of VCM is in the Material Safety Data Sheet available from QVC: